The Sim Corder Harrison Mill stands as a powerful reminder of what thoughtful engineering excellence can achieve. It blends beauty, function, and endurance. Set against a natural landscape, it tells the story of early innovation powered by the simplest forces of nature. Built long before modern machines and digital tools, this mill continues to teach valuable lessons about efficiency, design, and resilience.

Its story begins with a vision. The people behind the mill understood the land and its resources. They knew how to work with nature instead of against it. They combined local knowledge with hands-on skill to craft a structure that was not only useful but enduring. Every part of the mill serves a purpose, and every design choice reflects intention and care.

Water as Power, Nature as a Partner

The heart of the mill lies in its use of water power. A nearby stream provided a steady, renewable energy source. The builders used the natural flow of water to drive a large wooden wheel. As the water turned the wheel, it transferred motion to the internal machinery. This simple yet effective design enabled the mill to run day after day with minimal fuel and waste.

They designed channels and gates to control the water flow. This allowed the system to adapt to seasonal changes. In dry months, the mill could still function with reduced power. During heavy rain, the controls kept the machinery from overloading. This balance between artificial systems and natural forces shows a deep respect for the environment and a keen understanding of its rhythm.

A Structure Built for Strength and Time

The Sim Corder Harrison Mill was built with solid materials. The main frame was made of strong timber, fitted together by skilled hands. These wooden beams were supported by a stone foundation that kept the building stable over the years. The frame flexed just enough to absorb vibrations from the machines, but it remained firm and secure.

Ventilation and drainage played a big role in preserving the structure. The builders placed openings to allow air to flow freely, helping prevent moisture damage. The sloped roof shed rain and snow with ease. These small but important features helped protect the wood and stone. Even now, they show how much thought went into keeping the mill standing through the seasons.

A Simple Flow for a Complex Task

The inside of the mill was designed for movement. Grain entered at the top level and followed a downward path. It passed through grinding stones and sifters, eventually reaching the collection bins at the bottom. Gravity did most of the work. This made the process fast and required little extra effort from the workers.

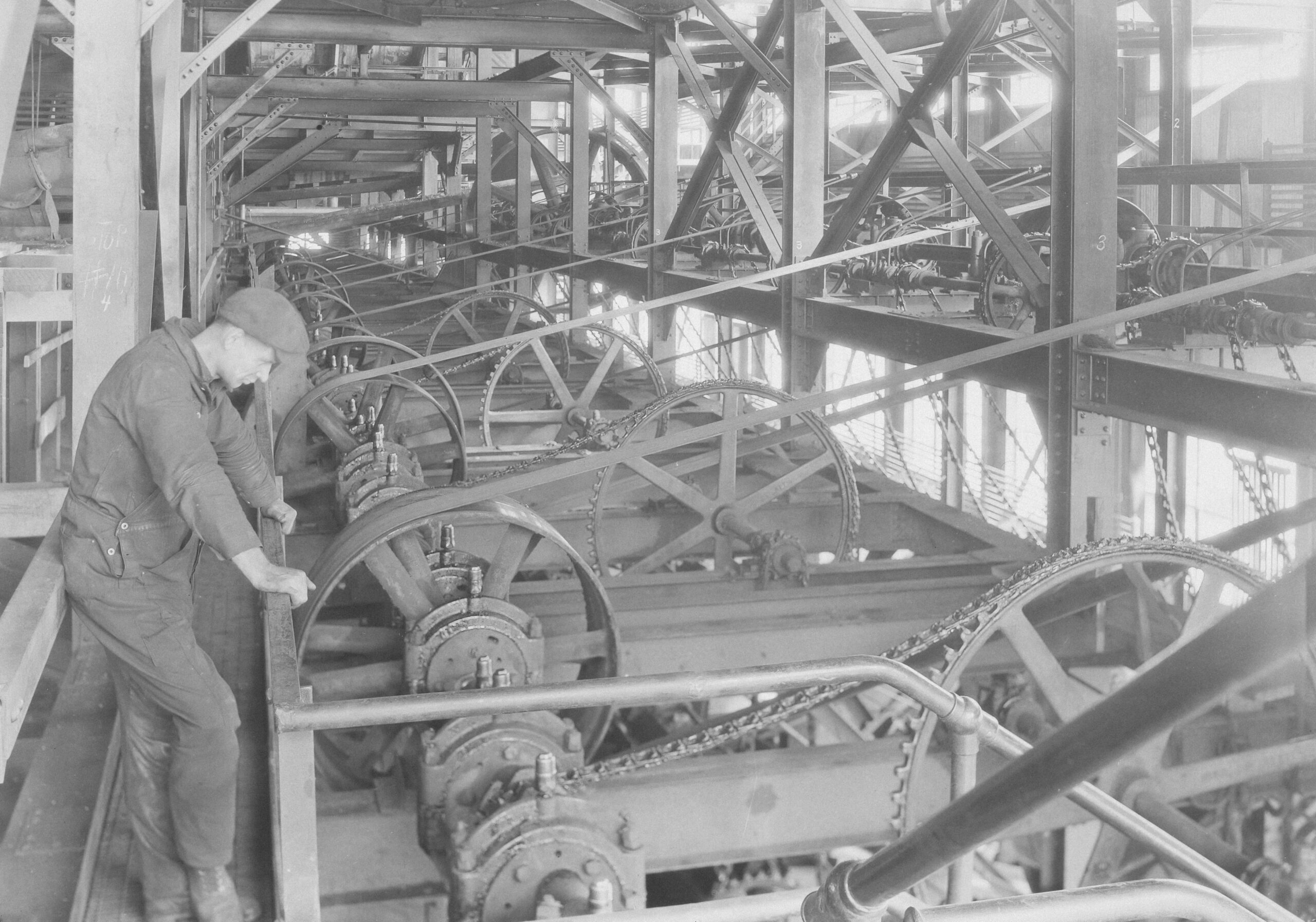

Machines inside the mill were powered by the waterwheel outside. Gears, shafts, and belts worked in harmony. Each machine was placed with care to avoid wasted motion. The layout helped workers stay safe and efficient. The entire process was smooth, with no step out of place. This attention to workflow still impresses engineers who study the mill today.

More Than Machinery, A Community Anchor

The mill did more than grind grain. It brought people together. Farmers brought their harvest to be processed. While they waited, they shared stories and news. The mill became a meeting place. It helped form bonds between neighbors and kept the local economy.

Its success supported many lives. Local tradespeople found work building and maintaining the structure. Merchants gained access to more food and supplies. Families relied on it as part of their daily lives. The mill gave more than flour. It gave security, purpose, and a sense of pride to the community it served.

A Testament to Practical Design

Every part of the mill reflects practical thinking. The materials were chosen for their strength and availability. The layout made sense for how people worked. Repairs could be done quickly, with tools and skills found nearby. This reduced downtime and kept the mill productive even in tough conditions.

Even the building’s aesthetics were guided by purpose. Windows let in light and let out heat. Doors were placed for easy loading and unloading. Nothing was done for show. Yet the result is a structure that looks as impressive as it is useful. It proves that form follows function can still lead to beauty.

Preserving the Past with Modern Tools

Today, the Sim Corder Harrison Mill stands as both a museum and a monument. Teams of historians, engineers, and craftsmen work to preserve it. They study the original techniques and use them when making repairs. Where modern tools help, they use them gently. Their goal is to protect the mill’s spirit, not replace it.

By keeping the mill active, they keep its lessons alive. Visitors can see the machines at work and understand how simple ideas created lasting results. School groups, engineers, and tourists all come away with new respect for what people achieved with limited tools but unlimited care. The mill continues to inspire new generations.

Lessons That Still Matter Today

In a world of rapid change and throwaway products, the mill stands apart. It shows that good design lasts. It teaches that understanding the land and its patterns leads to smarter solutions.

Engineers today face new challenges. But they can still learn from the choices made at the Sim Corder Harrison Mill. Use what you have—design with care. Respect the forces around you. These are timeless lessons. They work as well now as they did centuries ago.

A Living Blueprint for the Future

The Sim Corder Harrison Mill is not just part of history. It is a working example of how we can build better. It offers ideas for energy use, sustainable materials, and community-centered planning.

Its story is not finished. As long as the mill stands, it will keep shaping the way people think, build, and connect. Its power lies not in size or scale, but in the strength of its purpose and the care behind its creation. That is what makes it a true marvel. That is why it still matters today.